The Oxleas NHS Foundation Trust has invested significantly in restructuring and revitalising the facilities at Queen Mary’s Hospital in Sidcup. The Trust appointed Technical Manager Jack Costello to support their long-term asset management goals to refurbish and maintain their buildings for the future.

With the improvements planned across 5 phases, the large-scale refurbishment project at Queen Mary’s Hospital would incorporate a breadth of works, including clinical accommodation and internal refurbishment. As part of the Trust’s planning, there was an immediate desire to prolong the roof’s life as much as possible and restore the existing system before any water ingress or further problems occurred.

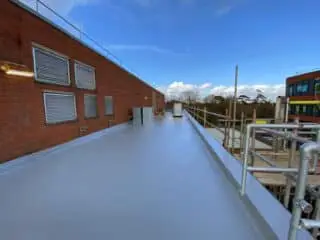

Jack conducted a detailed roof condition survey and site report to assess the existing substrate of the 2,000 sqm roof, revealing a mastic asphalt system applied directly to the concrete deck. The existing system needed restoration, making it eligible for refurbishment to prolong its serviceable life.

The hospital would need to remain fully operational throughout the phased works, with minimum disruption to patients and daily staff operation across the site.

Given the sensitive nature of the active hospital, it was an essential requirement for the new waterproofing system to reduce the threat of fire risks during installation and eliminate the need for naked flame torch-on applications. See here to read more on when to include flame-free systems in a roofing project.

The rooftop at Queen Mary’s included numerous plant equipment and coolers that could not be moved as they supplied essential services to the theatres and wards below. The existing flat roof contained a series of awkward detailing requiring a durable waterproofing solution that could easily accommodate the challenges.

Working closely with the main contractor Galliford Try, Jack specified Garland’s flame-free Dura-Coat cold applied liquid waterproofing system. This unique MMA resin has been developed to eliminate the need for hot works or naked flame. It is the ideal waterproofing system for sensitive sites such as healthcare estates with a strict zero flame policy.

The Dura-Coat system comprises a 3 part application process of Dura-Coat Primer, Membrane and Top Coat, providing a homogenous watertight seal across the roof surface and excellent crack bridging properties if used for remedial repair projects.

The roof at Queen Mary’s consisted of a network of steel beams that supported the various coolers and plant equipment across the site. It was essential to ensure that the plant equipment was not disturbed during the works, which could cause the deactivation of the critical services they supplied to the hospital. The liquid waterproofing system, Dura-Coat, was the perfect solution for the complex roof structure as it is ideally suited for sealing the more awkward detailed areas such as upstands and ventilation points.

Garland UK’s highly skilled approved contractor, Inspire Contracts, utilised Dura-Coat’s rapid curing time of as little as 30 minutes to deliver a high-quality installation. With a series of extendable rollers, the cold-applied liquid waterproofing system was applied evenly underneath the active plant equipment efficiently, ensuring no disruption to the hospital’s daily operation.

The roof works, carried out during phase 2 of the Trust’s extensive refurbishment project, were completed on budget and on time in just 9 weeks. With multiple stakeholders involved in the project, Jack visited the site twice a week during the Dura-Coat installation to provide regular quality checks and detailed progress reports to all parties.

Jack conducted a rigorous final inspection of the installation quality on project completion. Garland UK supplied The Oxleas NHS Foundation Trust with a market-leading 20 year Single-Point Guarantee on completion, which covers the project’s design, waterproofing system and installation liability, providing complete peace of mind for the future of the hospital’s roofing assets.