Flame-free roofing systems have become an increasingly important solution to modern flat roofing requirements, significantly mitigating the danger of roof fires. They can be used with traditional torch-on systems to detail areas at a high risk of combustion. There is also increasing demand for their use as a standalone system, completely removing the requirement to use a naked flame during installation. This has proven to be especially popular with the education, healthcare and emergency services sectors, which due to the sensitivities of their sites, often have a strict zero flame policy.

We will discuss how flame-free roofing systems can be incorporated to mitigate the risk of fire on your project.

What is a Flame-Free Roofing System?

Flame-free roofing systems use self-adhesive modified bitumen membranes combined with hot air welding; or cold-applied liquid coatings; or a combination of both, to achieve the same durability and robust waterproofing benefits as traditional torch-on solutions, without the need for a naked flame.

Benefits include:

- No naked flame

- Reduce fire risk for contractors and clients

- Robust waterproofing performance

- Fast application

- Reduced on-site waste

- Reduced CO2 emissions

Fire Risks in Construction

The risk of fire during construction can be high if not properly mitigated. This is predominately due to the need to perform what is known as hot works, which BS 9999:2017 defines as “any procedure that might involve or have the potential to generate sufficient heat, sparks or flame to cause a fire”.

The hot works associated with roof construction are cutting, grinding, welding, bitumen boilers and gas torches for torch-on membranes installation and drying substrates prior to the application of materials. Last year hot works accounted for approximately one-fifth of construction-related fires. Between 2013 and 2014, there was, on average, one fire per month on commercial buildings during roof construction. Most of these were caused by using gas torches whilst drying the roof substrate.

Dangers of roof fires include:

- Loss of life

- Risk of injury

- Damage to property

- Delays in construction

- The cost incurred for remedial work

- Increased insurance costs

- Litigation

Construction (Design and Management) Regulations (CDM) 2015

CDM (2015) is an overarching health and safety legislation that defines the roles and legal responsibilities of everyone involved with any part of a building project.

As designated CDM (2015) designers, Garland UK Technical Managers are on hand to offer their expert recommendations. After completing a complimentary detailed consultation and site visit, we can help:

- Specify the appropriate design for the roof build-up, taking into account the building use

- Provide core samples and moisture content analysis.

- Provide detailed existing site surveys containing a photographic record.

- Clearly identify high-risk areas.

We will provide a bespoke specification for your particular roofing needs, with the best system for your building type and budgetary requirements. This specification will always have assessed and designed out or greatly reduced the risk of fire. This is achieved by specifying flame-free systems wherever possible and providing clear flame-free installation instructions to contractors to ensure that all work follows NFRC Safe2Torch guidelines at all times.

NFRC Safe2Torch

In July 2017, the National Federation of Roofing Contractors (NFRC) introduced the Safe2Torch scheme, with the aim of reducing the risk of roof fires in the flat roofing industry caused by the use of gas torches. This is achieved through the application of the following principles.

Safety through design

Those who create risks have a responsibility to manage those risks. Therefore, it is essential to ensure all fire risks are identified at the survey stage, so their mitigation can be designed from the project’s inception.

Safety through responsible specifications

High-risk areas must be identified, and suitable flame-free systems must be specified for use in these areas. Importantly, where it is impossible to determine the make-up of the roof, Safe2Torch treats these areas as high-risk by default.

Torch-on applications are only permitted in areas that are demonstrable to be safe.

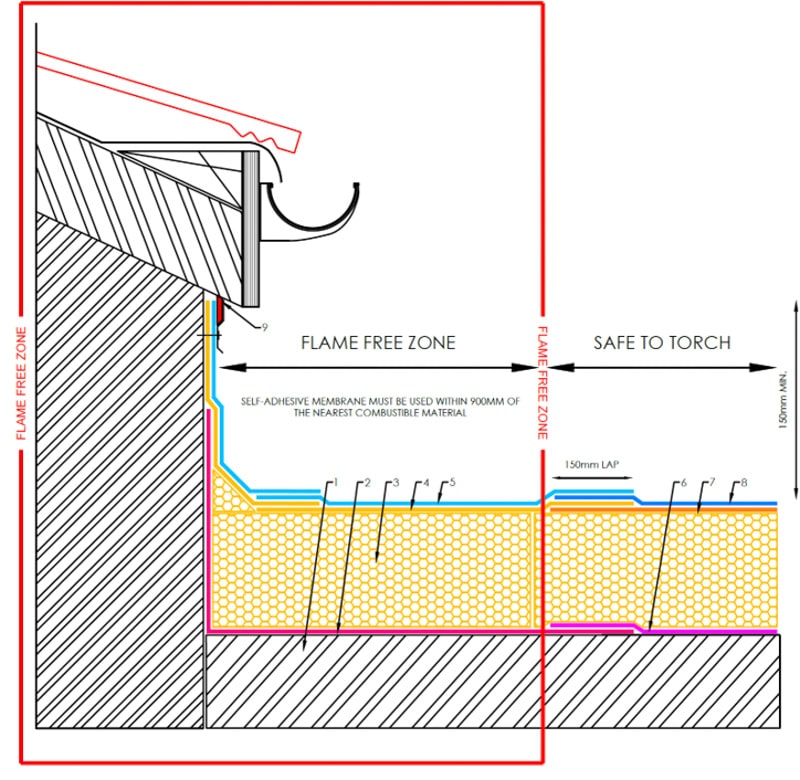

This is clearly demonstrated in the image opposite. The area shown in red is considered high-risk as it is too close to the pitched roof, which may contain materials, such as timber, that are at risk of combustion. This area is unsafe to torch, and a flame-free product must be used.

Safety through application

Installing contractors has as much a responsibility as designers in making the construction process as safe as possible. Contractors must perform their own risk assessments before the project starts and continually as work proceeds, as risks that were unknown during the design stage may reveal themselves during the construction process.

Flame-free exclusion zones are created, within which only flame-free roofing products may be used, extending 900mm from any combustible material or high-risk details. Again if there is any doubt at all, a flame-free solution must be used by default. Only if demonstrable that an area is safe can torch-on applications be used.

Guaranteed compliance to all statutory obligations

The Safe2Torch framework, when used with Garland UK’s roofing systems, means that your project is guaranteed to comply with all current regulations, standards and legislation.

Both as members of the NFRC and designated designers under CDM (2015), Garland UK always follows Safe2Torch guidance and codes of practice. As such, we will specify a flame-free system wherever possible to reduce the risk of fire.

Garland UK’s Flame-Free Systems

Our flame-free systems can be used as a standalone product or alongside hot works bituminous membranes depending on the needs and requirements of the building project.

StressPly Flex SA

Combining the use of self-adhesive membranes, hot air welding and solvent-free adhesives, StressPly Flex SA System is Garland UK’s premier flame-free modified bitumen system.

Dura-Coat, Dura-Walk and White-Knight

Garland UK’s family of cold applied liquid coatings, Dura-Coat and White-Knight chemically cure quickly once applied, allowing for fast and safe installation.

All our flame-free systems share some key features:

- Up-to-20-year Single-Point Guarantee

- Tested to the European fire safety standard using CEN/TS 1187 Test 4 and classified to BS EN 13501-5 achieving the highest fire-resistance rating of Broof(t4)

- Garland waterproofing systems can be used without restriction in compliance with Building Regulation and Approved Document B

Each system has its own benefits so it is always best to talk to your local Garland Technical Manager to find out what will work best for you.

Explore Your Flame-Free Roofing Solutions

Garland UK’s highly skilled Technical Managers are on hand to help. With their wealth of expertise, they will be able to assess the viability of your roof to incorporate our flame-free systems and find the right bespoke solution for even the most complicated roofs.

Garland UK has a national network of approved contractors with extensive expertise and training in Safe2Torch flame-free installation, who you can trust to complete your work safely and to the highest professional standard all supported by our leading Single-Point Guarantee.

“The risk of a roof fire caused by hot works must never be overlooked. Flame-free roofing systems ensure fire risks are considered and designed out of your roofing project before work commences.”

Ben Whitemore, Technical Product Manager, Garland UK