What is Cut Edge Corrosion?

Cut edge corrosion is a common issue that affects aged metal profile roofs, predominantly around the sheet laps and sheet end areas. During the manufacturing process, a layer of coating is applied to galvanised steel sheets to colour and provide extra protection. The coating varies by product, usually PVC, Polyester and PVDF are used for standard applications, for more corrosive environments specialist brand coatings such as TATA steel HPS 200 is often used in marine or coastal locations.

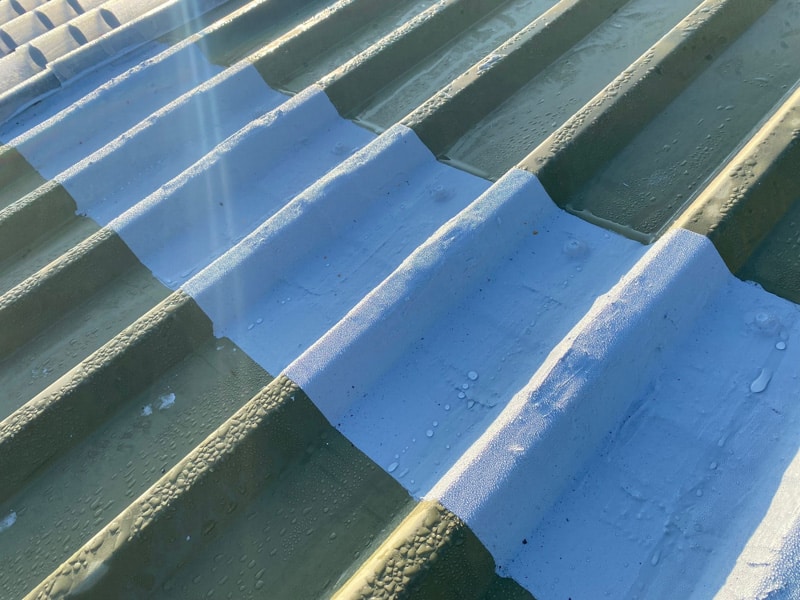

Once coated, the galvanised steel sheet is then rolled into large coils, before being sent to be cut and profiled to the tailored roof system specification. However, where the sheets have been cut it also creates an exposed untreated metal edge. Lacking a protective layer of coating, this edge is particularly vulnerable to corrosion caused by weathering.

Over time this corrosion can cause the protective coating to de-laminate from the underlying metal and begins to peel back from the sheet edge. This in turn exposes more of the metal to the effects of weathering, further exacerbating the problem. If left untreated this exposure will cause the metal to corrode and eventually perforate.

On any metal roof, coating peel back is inevitable when left neglected. Early detection and treatment of cut edge corrosion is vital to stop continuing coating peel back from the sheet edge. Left untreated, the damage will get progressively worse until a complete replacement of the roof sheets will be your only option for repair.

What to Look Out For?

As the name suggests cut edge corrosion is normally found at the edge of sheets. Look out for rusting or the protective coating peeling along any edge. The bottom of eaves are particularly vulnerable, as are any horizontal laps between sheets. Fixing points are another area that needs close attention. Washers may have degraded allowing water ingress, which will cause corrosion.

How to deal with Cut Edge Corrosion?

The first step is to get an expert assessment from one of Garland UK’s highly skilled Technical Managers. They will conduct a complimentary site survey, accessing the overall condition of the existing roof system and substrate. From this they will be able to ascertain what type of metal sheet material has been installed and provide you with a thorough Condition Report, outlining the technical analysis and findings from the site visit.

Garland UK recommends replacement options to remedy this issue. However, we can support our customers by offering cold-applied liquid coating treatments, such as the Dura-Coat system, that provides a watertight mid-term solution for any damaged flashing, edges or any other weakened surfaces found. This will buy time while phased works commence or sufficient budgetary allowances can be secured.

For this treatment, any loose coating is removed from the affected area with a wire brush before a robust coating solution is applied to local areas.

Tailored treatment for Cut Edge Corrosion

Cut edge corrosion is fundamentally inevitable as metal roof systems come to the end of their lifespan. Coated steel coil manufacturers guarantee their products for limited periods varying by performance and cost.

To ensure the integrity of the product our Garland UK’s network of approved contractors are trained to avoid the use of grinders, as this will strip the protective lamination. Instead, tin snips or a sheet metal nibbler are used when on-site cutting is necessary. This seals the two faces of the metal together and prevents delamination. Where standard cutting techniques are unavoidable, such as with composite PIR core panels, then the exposed edges are immediately treated with a protective coating by the installer.

Where cut edge corrosion has already progressed to the point of failure, with Garland UK’s R-MER CLAD metal roof system it is possible to overclad the roof structure whilst leaving the existing end-of-life roof in place. Using high-performance coated steel, such as TATA HPS 200, Garland’s profiled roofing solutions will rejuvenate the building and offer many years of weatherproofing.

Partners for the life of your building

Regular inspection and maintenance is always essential to maintain the integrity of your roofing asset. This allows for potential problems to be spotted early, minimising any remedial works that will be needed to restore and repair your roofing system. Regular maintenance will guard against leaks and extend the life of your system so that a complete roof replacement is not needed sooner than expected.

Garland UK believes in partnering with you for the life of your building. As part of our PartnerCare service, the Garland UK aftercare programme will provide you with regular roof inspection reminders, giving you all the support and guidance you need. From annual ‘health check’ site visits by your dedicated Technical Manager to providing general maintenance schedules and tailored cleaning plans for your roof.

“Getting us in for regular inspections and maintenance is always the best way to maintain the integrity of your roofing asset.”

Dave Campos- Technical Manager