Methods to improve the circular economy in roof construction.

Whilst we have already touched on some of these techniques in passing, the following existing methods can contribute significantly to the circular economy of roof construction and merit a closer examination.

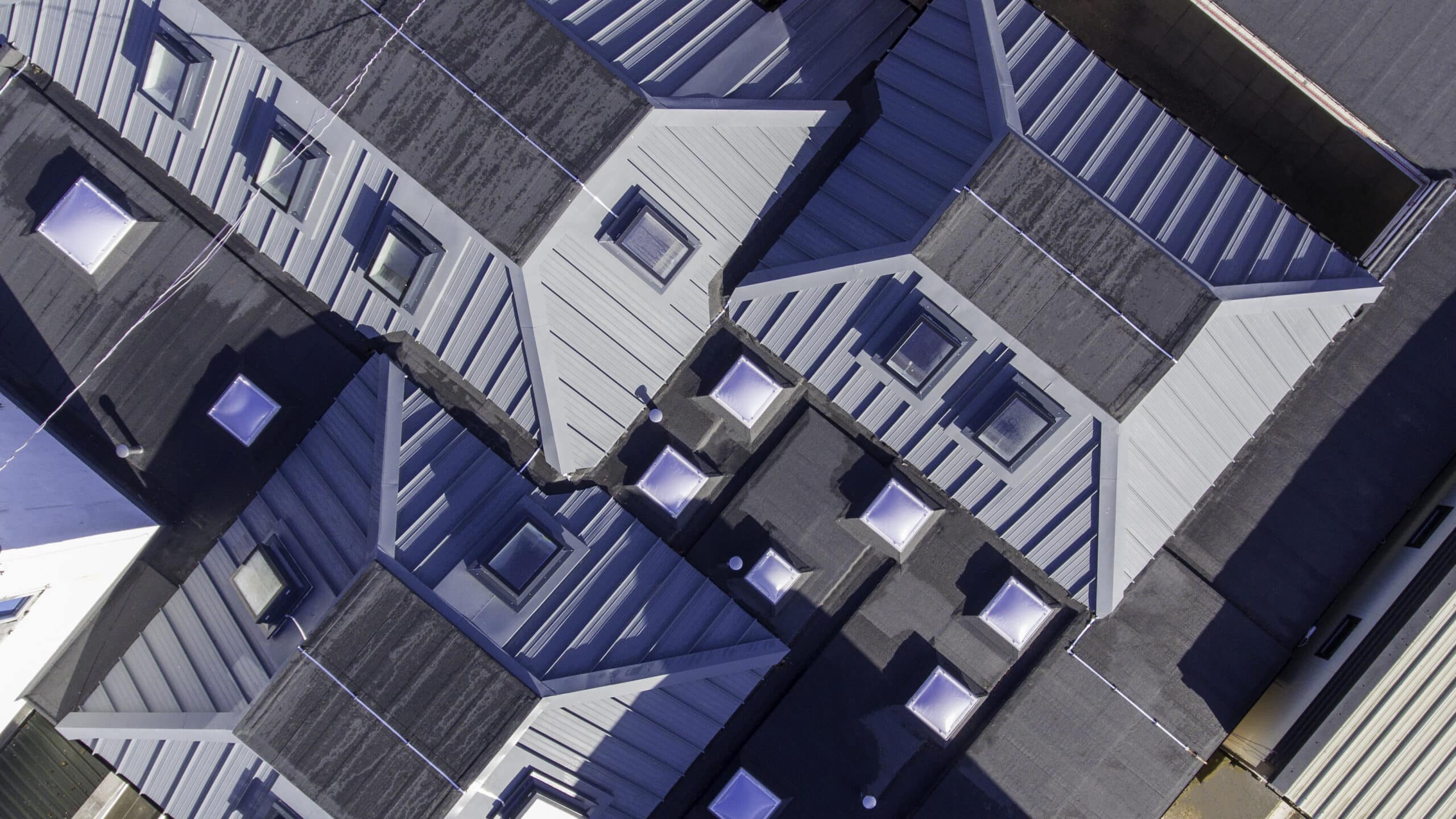

Roof Lifespan and Longevity

Roofing systems with a longer lifespan generate less waste, as they need to be replaced less often. This reduces the amount of material that ends up in landfills. Regular maintenance should also be carried out to ensure that any repairs needed are small and to increase the roofing system’s longevity further.

When waterproofing does finally fail beyond repair, encapsulation should be considered. By adding a new layer of roofing material, the lifespan of the roof is extended, reducing the need for frequent roof replacements and the associated waste. It also requires less material than a complete roof replacement, as the existing roofing material is still in place to provide a suitable substrate for the new system. This, in turn, reduces construction transportation emissions and costs. Often the encapsulation layer can also help to improve the energy efficiency of the building, reducing the amount of energy needed to heat or cool the building and thus reducing carbon emissions even more.

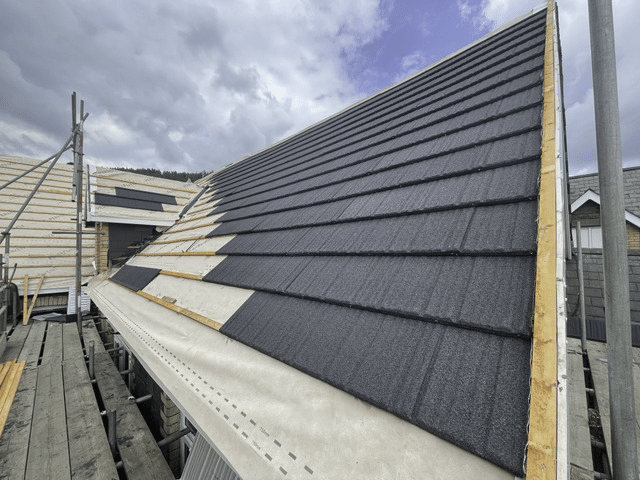

Recyclable Roofing Systems

Choosing roofing systems that can be recycled is an essential component in creating circular economies in roofing construction. However long-lasting a product is, eventually it will fail in a way that cannot be economically repaired. Recycling the materials used at the end of life significantly reduces the embodied carbon of the material. Recycling produces far less carbon than producing something directly from natural resources, helps to conserve finite resources, and helps lower material costs by increasing supply, also reducing the environmental impact of natural resource extraction. Of course, the more recyclable a roofing system is, the less waste it produces and the more sustainable it is as a product.

Metal roofing systems are 100% recyclable and can be produced in a perfect circular economy. Metals can be easily and cost-effectively resmelted over and over again, indefinitely, forever. Metal roofing systems that are well maintained are also some of the longest-lasting systems available. Metal roofing is an easy and sensible choice when trying to encourage the most efficient circular economy possible in roofing construction.

However, many people are unaware that bitumen roofing systems can also be recycled. This is undoubtedly a more difficult and costly process at present. Currently, the most efficient recycling method is to use it to create bitumen for use in road construction. The old bitumen roofing membrane is crushed and ground, mixed with aggregate, and ready to go.

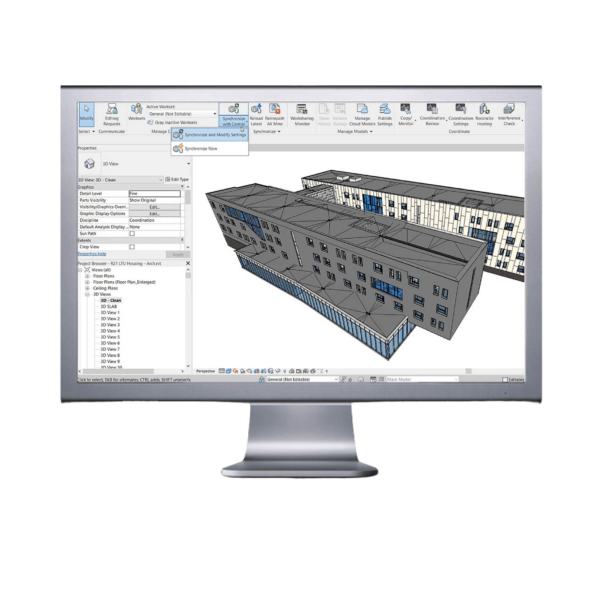

Design for Disassembly (DfD)

Roofing systems should be designed for easy removal and recycling whenever possible at the end of their service life. There are a number of techniques to make this process easier. Ideally, a roofing system should be designed using standardised components that can be easily removed and reused.

Materials used to make a roofing system should be considered for compatibility to make separation as simple as possible. Standardised fixing connectors and fastening systems should be used to speed up disassembly. Where feasible, each product should be labelled or coded to provide information about its materials, manufacturer and intended reuse. It can also help to facilitate end-of-life processing.

Metal roofing systems can already be considered DfD as they are easily dismantled and 100% recyclable. Reinforced Bitumen Membranes are more time-consuming to dismantle as by design, the layers fuse together, but even they can be dismantled by skilled contractors.