According to the UK government in England alone, the construction industry is responsible for over 60 million tonnes of non-hazardous waste per year, with as much as 15% of materials delivered to site going immediately to waste. Although around 90% of this waste is recycled, this often involves ‘downcycling’, e.g. crushing building waste to use as hardcore, which is inefficient when the energy and carbon taken to create these materials are considered.

The built environment accounts for almost 40% of the UK’s total carbon emissions and up to 11% of total global emissions. Utilising circular economy methodologies can reduce our industry’s carbon emissions and simultaneously support the UK’s journey to Net-Zero by 2050.

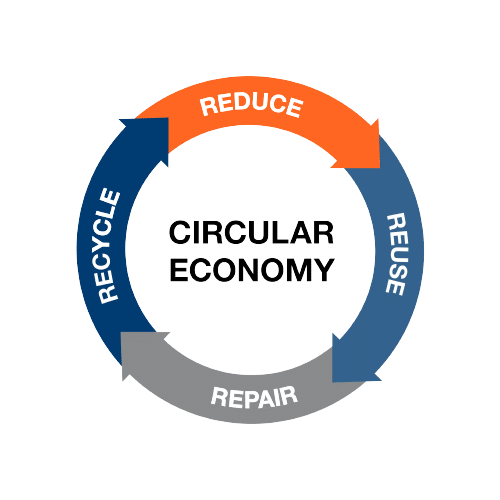

What is the Circular Economy?

Traditionally, natural resources are processed into products and disposed of when they reach their end of life. This is considered a linear economy. With the circular economy, you seek to make a product’s lifecycle cyclical instead.

The circular economy concept aims to reduce waste, conserve resources, and create closed-loop systems in which materials are continually reused, helping the industry produce more sustainable, resilient, and economically viable buildings now and in the future.

This is achieved by following these simple principles:

Reduce

If something was never used in the first place, it could never be wasted. By looking for innovative ways to reduce the amount of materials used during construction and utilising new technologies that manufacture sustainable, long-life and lightweight construction materials, less energy could be needed in the long term.

Reuse

By reusing materials, you save money and stop that material from ending up in landfills. There is a long history in the construction of using reclaimed materials, and this tradition should be continued and expanded even further wherever possible.

Repair

It should always be the priority rather than replacing. A product’s or system’s lifecycle can be significantly increased by conducting proper maintenance, which is both cost-effective and carbon efficient.

Recycle

Where it is impossible or impractical to reuse or repair, then at the end of life, a product should be able to be recycled. Recycling can require far less energy than manufacturing something from raw materials and significantly reduces the embodied carbon of both the original and new products.

How does this affect roofing projects?

These principles can be applied to every stage of a roofing project, from the initial design to installation all the way through to the end of the life of the roof.

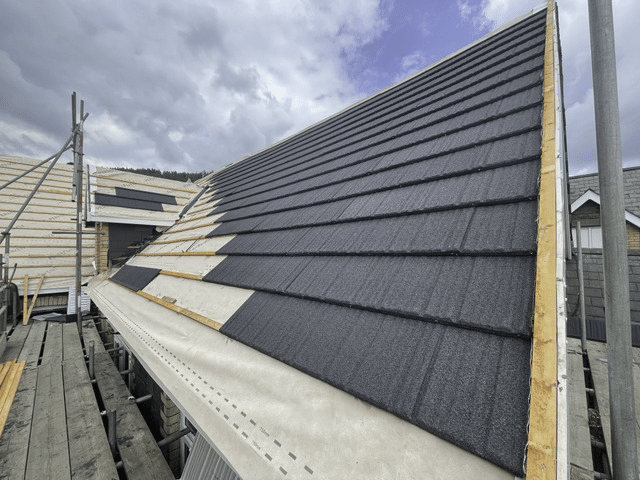

The initial design of a roofing project is perhaps the area where the most impact can be achieved. Potential waste can be easily assessed at this stage and designed out wherever possible. Roofing materials with the longest possible lifespan should be selected to lower the project’s embodied carbon as much as possible by delaying the need to replace the roof for as long as possible. This also has the added benefit of saving money in the long term. The chosen material should also ideally be easily maintained to maximise its lifespan.

Roofing systems that use a minimum of material in their construction would improve the circular economy of the system even further whilst making transportation less carbon-intensive and normally allowing for quicker and easier installation on-site. By specifying highly efficient insulation within the roofing design, the operational costs of the whole building can be reduced, saving energy and reducing carbon emissions. Of course, nothing can last forever, so choosing a roofing material that can be recycled at the end of its life will help even further.

On-site, the roofing contractors can continue to contribute to this process in a number of ways. On new build installations, care can be taken to minimise the generation of waste during installation by using best practice installation techniques and appropriate specialist tools.

Retrofit projects may present opportunities to reuse existing materials that are already present. For example, if a waterproofing layer of a roof was to be removed and replaced, then the roof deck may very well be perfectly reusable as it is or with minor repairs. Of course, leaving the existing roofing structure in place and overlaying the new waterproofing system would be even more efficient at eliminating waste and reducing the project’s embodied carbon whilst also saving the cost of removal and disposal.

Where waste is unavoidable, it should be properly managed. Site Waste Management Plans (SWMPs) should always be developed. Contractors should be trained to distinguish which items are reusable and recyclable. Software such as the BRE SmartWaste can provide detailed reporting and logging of waste generated on-site and the contents of each skip. This allows for areas of improvement to be analysed and ensures that all materials that can be reused or recycled don’t end up in landfill.

Methods to improve the circular economy in roof construction.

Whilst we have already touched on some of these techniques in passing, the following existing methods can contribute significantly to the circular economy of roof construction and merit a closer examination.

Roof Lifespan and Longevity

Roofing systems with a longer lifespan generate less waste, as they need to be replaced less often. This reduces the amount of material that ends up in landfills. Regular maintenance should also be carried out to ensure that any repairs needed are small and to increase the roofing system’s longevity further.

When waterproofing does finally fail beyond repair, encapsulation should be considered. By adding a new layer of roofing material, the lifespan of the roof is extended, reducing the need for frequent roof replacements and the associated waste. It also requires less material than a complete roof replacement, as the existing roofing material is still in place to provide a suitable substrate for the new system. This, in turn, reduces construction transportation emissions and costs. Often the encapsulation layer can also help to improve the energy efficiency of the building, reducing the amount of energy needed to heat or cool the building and thus reducing carbon emissions even more.

Recyclable Roofing Systems

Choosing roofing systems that can be recycled is an essential component in creating circular economies in roofing construction. However long-lasting a product is, eventually it will fail in a way that cannot be economically repaired. Recycling the materials used at the end of life significantly reduces the embodied carbon of the material. Recycling produces far less carbon than producing something directly from natural resources, helps to conserve finite resources, and helps lower material costs by increasing supply, also reducing the environmental impact of natural resource extraction. Of course, the more recyclable a roofing system is, the less waste it produces and the more sustainable it is as a product.

Metal roofing systems are 100% recyclable and can be produced in a perfect circular economy. Metals can be easily and cost-effectively resmelted over and over again, indefinitely, forever. Metal roofing systems that are well maintained are also some of the longest-lasting systems available. Metal roofing is an easy and sensible choice when trying to encourage the most efficient circular economy possible in roofing construction.

However, many people are unaware that bitumen roofing systems can also be recycled. This is undoubtedly a more difficult and costly process at present. Currently, the most efficient recycling method is to use it to create bitumen for use in road construction. The old bitumen roofing membrane is crushed and ground, mixed with aggregate, and ready to go.

Design for Disassembly (DfD)

Roofing systems should be designed for easy removal and recycling whenever possible at the end of their service life. There are a number of techniques to make this process easier. Ideally, a roofing system should be designed using standardised components that can be easily removed and reused.

Materials used to make a roofing system should be considered for compatibility to make separation as simple as possible. Standardised fixing connectors and fastening systems should be used to speed up disassembly. Where feasible, each product should be labelled or coded to provide information about its materials, manufacturer and intended reuse. It can also help to facilitate end-of-life processing.

Metal roofing systems can already be considered DfD as they are easily dismantled and 100% recyclable. Reinforced Bitumen Membranes are more time-consuming to dismantle as by design, the layers fuse together, but even they can be dismantled by skilled contractors.

The Future of The Circular Economy in Construction

There is a growing emphasis on sustainability in the construction industry as building owners and operators demand more environmentally friendly and resilient buildings. This will drive investment and innovation within the industry.

Waste management innovations

There will be an increasing focus on innovative waste management techniques, such as creating closed-loop supply chains and new recycling technologies, to reduce waste and conserve resources.

New construction methods

The adoption of modular construction methods and building information modelling (BIM) technologies will significantly improve the construction sector’s circularity by reducing waste and making reuse and recycling even easier.

Government Legislation

The UK government is likely to continue to support and promote the circular economy in construction through legislation. The government has already legally committed to achieving Net-Zero goals by 2050 and will likely introduce increasing environmental protection measures to ensure that this is achieved

Garland UK is committed to using the circular economy principles to help us achieve our goal of being Net-Zero by 2032.

“The Circular Economy is an essential component in reducing the waste produced during construction and should play a vital role in reducing carbon emissions throughout the industry.”

Daniel Crowley, Technical Manager, Garland UK